Before you can integrate your operational technology (OT) with your information technology (IT), you first need to assess all your plant equipment, identify gaps in their connectivity and, finally, teach them to communicate with one another.

Yves Dandurand is the President of Adfast, a manufacturer of sealants and adhesives. Dandurand wanted to add connectivity to his hydraulic mixers for one very simple reason: “If we could control product quality in real time and at every stage of production, it would allow us to take action as soon as an issue was detected. That way, we wouldn’t have to destroy entire product batches because they failed to meet specifications.”

But Dandurand ran into a problem: even though the enormous basins at his plants were automated, they were not designed to be connected to a network. “The machinery was equipped with control systems dating back to the 1990s. They simply weren’t connectible! On the other hand, the machines were very solid, they didn’t break down and they had a lifespan of 20 to 25 years. Replacing them was out of the question,” Dandurand explains.

Dandurand’s dilemma is typical of companies attempting to make the switch. Enabling OT connectivity is both the foundation and the biggest challenge of any digital transformation. If you want to be able to collect and process production data in real time, your OT has to be capable of communicating with your IT systems. And for this to happen, you need to set up connectivity infrastructure to link OT with IT.

Identifying user needs

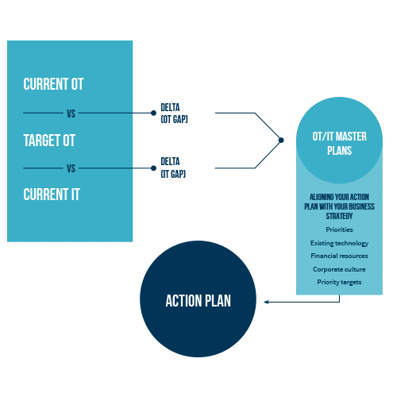

To build the bridge between OT and IT, companies must make a range of decisions concerning technology. For example, they must choose which equipment will capture data, what software and network type they will use and which firewall solution will separate OT from IT. “The analysis of OT needs and IT development requirements is carried out through what’s called an OT/IT master plan,” explains Patrick Caron, Delivery Manager and Senior Advisor for Industry 4.0 at NOVIPRO.

André Michel, the President of Efficient Plant Inc., specializes in the first component of the master plan, namely OT needs analysis and system implementation. “We start by examining the structure of existing systems and their communication network. Then, we identify user needs, which are the needs of the employees who will be using the systems and equipment. Finally, we establish a network topology based on the needs we’ve identified with a view to implementing the new systems,” André Michel explains.

To make this possible, Michel uses templates developed by the Manufacturing Enterprise Solutions Association (MESA), which are the Industry 4.0 equivalent of ISO standards. But even with this guidance, transitions can still be a headache for some businesses.

“At production sites, it’s not uncommon to find machines controlled by old PCs that use Windows 95. Such systems can’t communicate with more recent technology, and unfortunately the manufacturer doesn’t exist anymore. When this is the case, the upgrades are more involved. You have to rebuild the control system, and that’s just to continue using the same machinery as before but with a new version of the software,” says Michel.

Dandurand was prepared to make that compromise. “In the end, we installed new control systems on our old mixers, and we reprogrammed everything. Luckily, the logistics upgrade wasn’t too complicated in our case.”

Transforming your company’s culture

Connectivity isn’t just a technological challenge. There’s also the human factor. “People working in OT need to learn to work together with their IT colleagues in order to establish a joint IT-TO integration plan,” says Michel. “This sometimes leads to conflicts of culture between engineers and IT professionals. The work of IT staff tends to be transactional in nature, focusing on a series of successive operations. Employees in OT, meanwhile, operate in real time, with many things happening simultaneously. Those are two completely different views of the world.”

The challenge is especially difficult for IT staff who suddenly find themselves involved in decisions on which new equipment to acquire. According to Patrick Caron, “this is essential if we want the equipment’s connectivity solutions to be compatible with existing IT technology.”

Yves Dandurand also believes that corporate culture needs to adjust to the reality of Industry 4.0. “It takes people who are comfortable with the unknown, since you’re introducing new technologies. People who are open-minded and prepared to work with colleagues from other generations—younger or older—and who are willing to accept challenges to their ways of thinking.”

In other words, embracing Industry 4.0 requires people who are prepared to evolve together with their company.

Read the next article from our 4.0 transformation series : Are quebec’s IT departments ready for industry 4.0?